Case study

Data center filter installation plan

The value created by DTAF

Create value for customers

19,000 dollars saved due to longer lasting filters.

Good brand supplier

10,000 dollars saved in energy consumption by choosing A+ filters.

Properly save human resources

Less labour, waste disposal and operational cost.

Customer:

Large multinational

Location:

The United States

Spain:

Datacentres

Data center air filtration solution scheme

DTAF recommends specialized air filtration solutions tailored to data centers, which prioritize equipment protection over human occupancy per EN16798-3. Our 30/30 ePM1₀ 50% pre-filters and high-efficiency 592x592x640 mm XLT ePM₂.₅ 50% bag filters offer large surface area, high dust capacity, and low pressure drop—reducing energy use and extending service life.

We complement this with zone-specific IAQ analysis to optimize performance. This approach minimizes dust accumulation on hardware, enhances energy efficiency, reduces waste, and ensures reliable, sustainable HVAC operation.

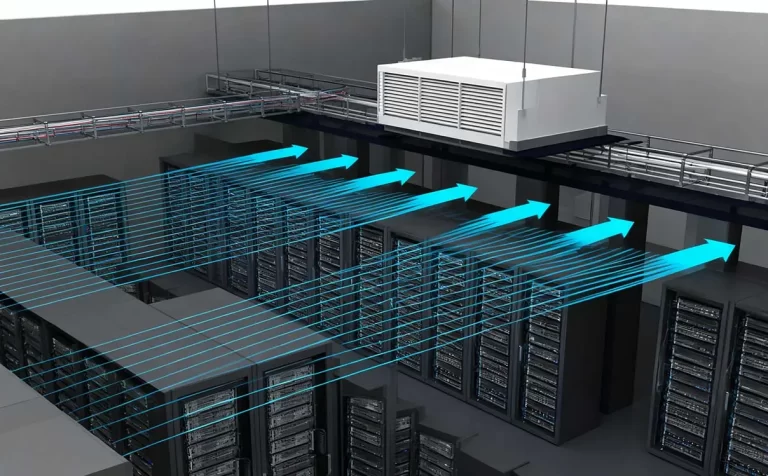

Scene ventilation design

We strictly control the inflow of fresh air to ensure a low environmental temperature, which is suitable for computer operation.

A state-of-the-art data centre designed for secure, efficient large-scale data processing. It features advanced climate and security systems to ensure reliability and data integrity. The facility emphasises sustainability through energy-efficient, eco-conscious operations.

Scene plan key points for breakthrough

- Frequent changes of their prefiltration was a key problem. The panel filters previously used were only able to be operational for one month before

they would become saturated - The secondary filters stage was causing a high pressure drop in the AHU which created higher energy consumption within the

system - The location of the datacentre meant that the filters would be exposed to high levels of dust concentrations. This meant that a high

dust holding capacity of the filter would be needed

After being put into use

Upon commissioning, an independent third-party conducted a comprehensive performance analysis of both rooms in accordance with ISO 14644-3:2022. Measurements focused on average particle counts for sizes 0.3 μm (by particle number) and 5 μm (particles/m³). The results not only confirmed compliance with ISO Class 8 requirements but also demonstrated particle concentrations approaching the stringent thresholds of ISO Class 7—where each subsequent class requires a tenfold reduction in particulate levels.

Furthermore, active monitoring and control via the AirImage sensor integrated with the CC 6000 system delivered significant energy savings, enabling the client to lower operational costs while minimising the environmental footprint of the facility.